Diversified upgrade in Dongguan

Guangdong's 'world factory' is going all-out to regain its dimmed glory by accelerating the development of high-end manufacturing industries and exploring the domestic market. Chai Hua reports from Dongguan.

Dongguan - dubbed the "world's factory" - has been intensely dependent on manufacturing and foreign trade to earn its global label. But while such reliance has propelled the city in Guangdong province to economic heights, it has come with drawbacks and potential risks.

To confront the underlying challenges that have surfaced recently, the local government and industry players are going the extra mile to turn the tide by beefing up the manufacturing sector and bolstering new pillar industries.

Dongguan's economic growth, closely tied to manufacturing and foreign trade, has had a roller-coaster ride in the past five years, with stirring ups and downs. The local economy peaked in 2021 when Dongguan joined the ranks of Guangzhou, Shenzhen and Foshan as the fourth city in Guangdong with a gross domestic product exceeding 1 trillion yuan ($139.2 billion). Technology giant Huawei's relocating its terminal product headquarters from Shenzhen to Dongguan made a substantial contribution to the economic spike. Huawei also invested about 10 billion yuan in a European-style town as its research and training base in 2014.

The shift has led to tens of thousands of Huawei employees commuting between the two cities daily, luring a host of suppliers, and creating a significant impact on the manufacturing business.

However, Dongguan's GDP growth slipped to the bottom in Guangdong last year amid a slowdown in smartphone shipments and a decline in overall foreign trade orders, which the city has traditionally depended on. In 2021, Dongguan's import and export trade hit a record high of 1.52 trillion yuan with total exports accounting for over 90 percent of its GDP, but it took a dive a year later, and continued its downward trend until the fourth quarter of 2023.

To plug the slump, the Dongguan authorities have designated 2024 as "the year of investment", with one of the key goals being to step up investment in the production process' technological renovation, and to promote the high-end and intelligent development of traditional manufacturing industries.

These measures have started to bear fruit. In the first two months of this year, Dongguan's foreign trade rebounded strongly with a year-on-year increase of 10.6 percent.

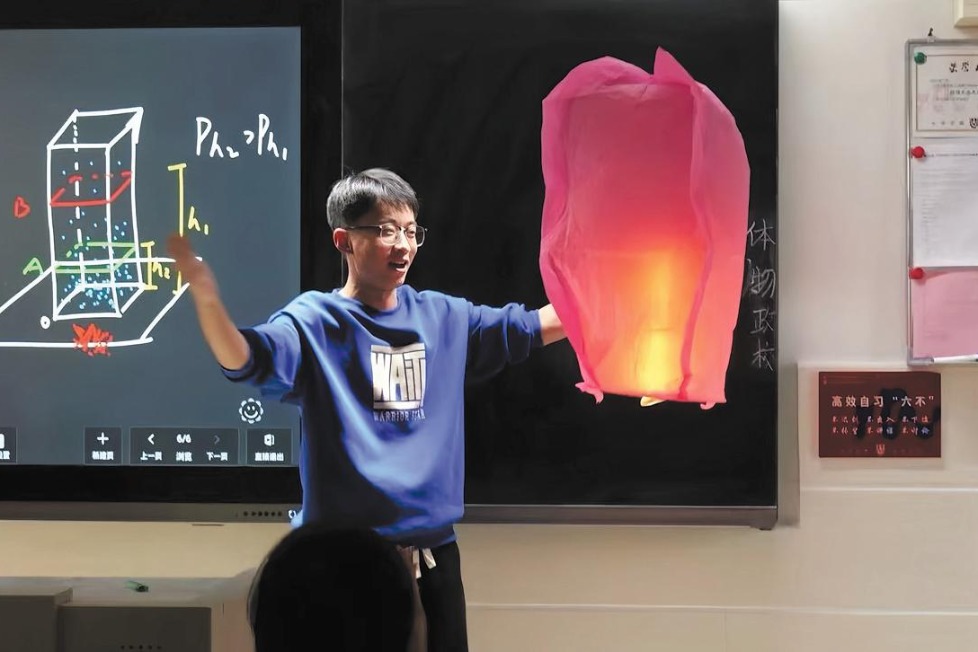

Automotive and intelligent manufacturing has been gaining pace in Dongguan in the past decade, with most of the factories setting up production lines with more smart machinery.

Guo Xiaocong, assistant vice-president of homegrown phone-maker Oppo, said the company has achieved an annual productivity growth of over 30 percent, with a comprehensive automation rate exceeding 80 percent. He expects Oppo to function as a "lighthouse factory" by next year.

As the largest pillar industry in Dongguan, the electronic information manufacturing business is moving toward higher-quality and more innovative high-end products. The trend aligns with the goal set in the outline development plan for the Guangdong-Hong Kong-Macao Greater Bay Area to develop a globally influential and competitive cluster of world-class high-end manufacturing industries, such as electronic communications, on the east bank of the Pearl River with Shenzhen and Dongguan at the core.

Manufacturing cradle

Some small and medium-sized factories in other traditional industries have also jumped on the bandwagon by improving efficiency and exploring new markets.

In Chang'an town - a manufacturing cradle with more than 7,000 jewelry factories manned by over 100,000 workers - some firms have set their sights on the domestic market because of the slump in overseas orders. "Domestic sales have grown remarkably, fueled by livestreaming platforms, such as Douyin," says Leng Yijun, president of the Dongguan Jewelry and Ornament Association.

He says the size of the domestic market has grown at least 10 to 20 times since 2019, and the momentum has prompted factories to adapt themselves to and optimize their operations. A jewelry factory, Miya, in Chang'an, used to take up to six months to complete an overseas order, but now, it's able to do it within six days.

The factory's owner, Yu Yonghua, explains he has introduced powder manufacturing processes that are typically used in making electronic products, into jewelry production to strengthen efficiency and product quality. The size of the manufacturing plant has expanded threefold and made it to the supply list of top livestreaming host Li Jiaqi and fast-fashion retailer Shein.

But one challenge remains - the company is still at the lower end of the value chain and struggling to shake off the "OEM" (original equipment manufacturer) label. "We're the hardest-working and most diligent in the entire production chain. Yet the return has been disappointingly low in terms of profit," laments Yu, who has been working in factories for over two decades.

Leng attributes the meager earnings to the lack of sales and marketing prowess. To avoid being caught up in a price war, he suggests that the local government provide guidance and support in improving marketing capabilities and the brand development of traditional factories.

IT incubation base

Besides upgrading traditional industries, Dongguan draws an array of innovators to create cutting-edge products. Songshan Lake Science City - a comprehensive national science center in the Greater Bay Area - and the new Binhaiwan Bay Area are two rising-star development projects.

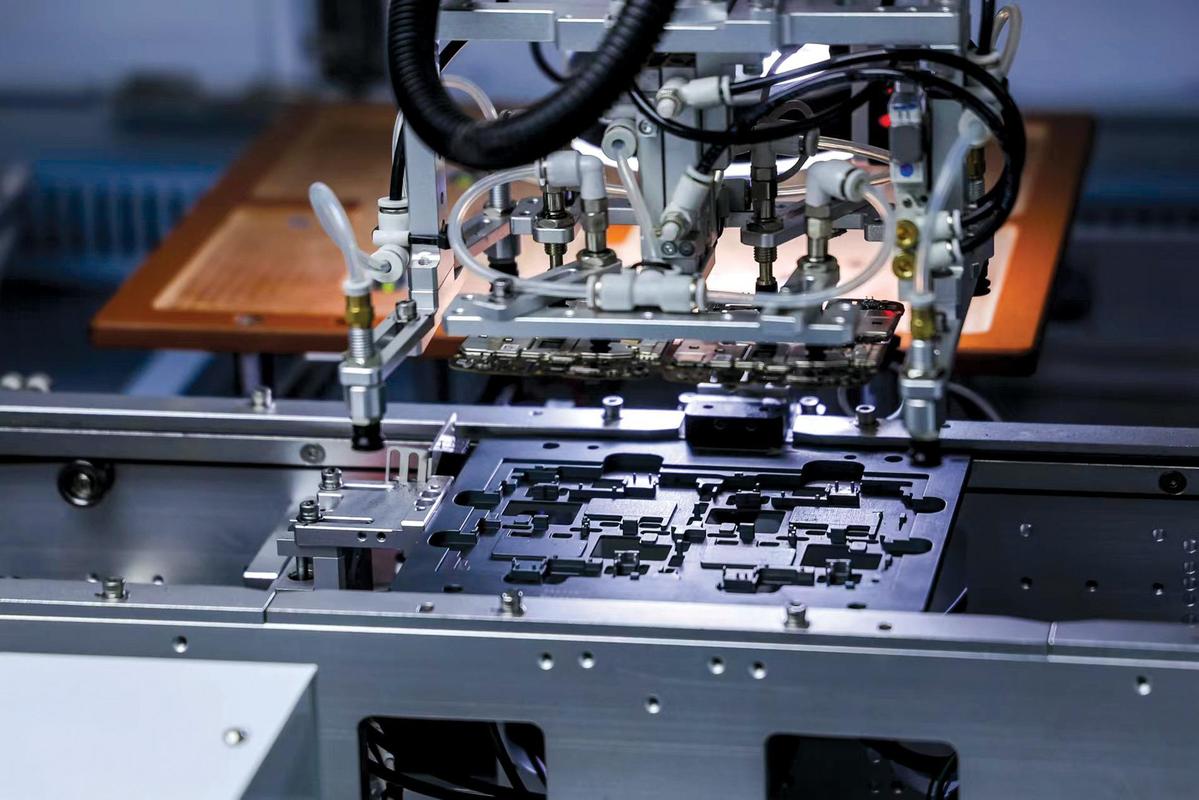

Li Zexiang, a professor at the Hong Kong University of Science, led a trio of experts in 2014 that set up a hardware technology incubator, XbotPark, at the Songshan Lake Science City.

So far, more than 80 hard-tech companies have emerged at XbotPark, with a staggeringly high success rate of over 80 percent. The cumulative valuation of leading startups has reached about 80 billion yuan. Among them, 15 percent have grown into unicorns - private startups with a valuation exceeding $1 billion - or quasi-unicorns.

A new campus at XbotPark was officially launched late last year. Covering about 110,000 square meters, the complex provides office space, an innovators' club, 3D printing and electronic labs, and two buildings of shared factories to conduct small-batch prototyping, product development, and testing. The facility, adjacent to Huawei's terminal headquarters, offers panoramic views of Huawei's European Town.

Li said at the new campus' opening ceremony the actual growth rate in many cities on the Chinese mainland had been quite high in the past few years, but it's now on the decline. Dongguan, with manufacturing at its core, is facing major challenges and pressure in terms of transformation as the city's previous drivers of growth have rapidly disappeared.

"Since the start of the nation's reform and opening-up, a large number of foreign investments have come to China. Dongguan had taken the opportunity and triumphed as the 'world's factory'. However, these factories are now encountering immense challenges and difficulties. If we were to remain solely reliant on being the 'world's factory', we would not be able to overcome the significant challenges ahead," Li said.

By strategically addressing these problems and embracing innovation, Dongguan's goal is to be on the ball, and continue its evolution as a leading global manufacturing hub.

Contact the writer at grace@chinadailyhk.com

- Guizhou achieves remarkable success in advancing high-quality development, official says

- Global influencers explore Yantai's wine culture

- China records sustained drop in environmental disputes

- Visitors impressed after boarding CNS Shandong on 'open day'

- Intl forum on ecology opens with over 1,000 domestic and foreign guests

- Green plums boost rural vitalization in Anhui