Clean energy boosted by tech, supply chains

NEVs in particular made efficiently, affordably in cities like Anhui's Hefei

HEFEI — A notion that China's burgeoning clean energy sector is propped up by market-distorting subsidies has been circulating about in Washington's corridors of power. Yet, an on-the-ground investigation of China's industrial powerhouse debunks the argument.

A glimpse into the inner workings of a solar panel facility revolutionized by augmented reality, a highly automated and intelligent assembly line of electric vehicles and a battery manufacturer using smart robotics in warehousing tells a compelling story.

Their cost competitiveness, a boon for global consumers and for initiatives to wean humanity off fossil fuels, is a direct result of tech prowess and the strength of supply chains, rather than a reliance on subsidies.

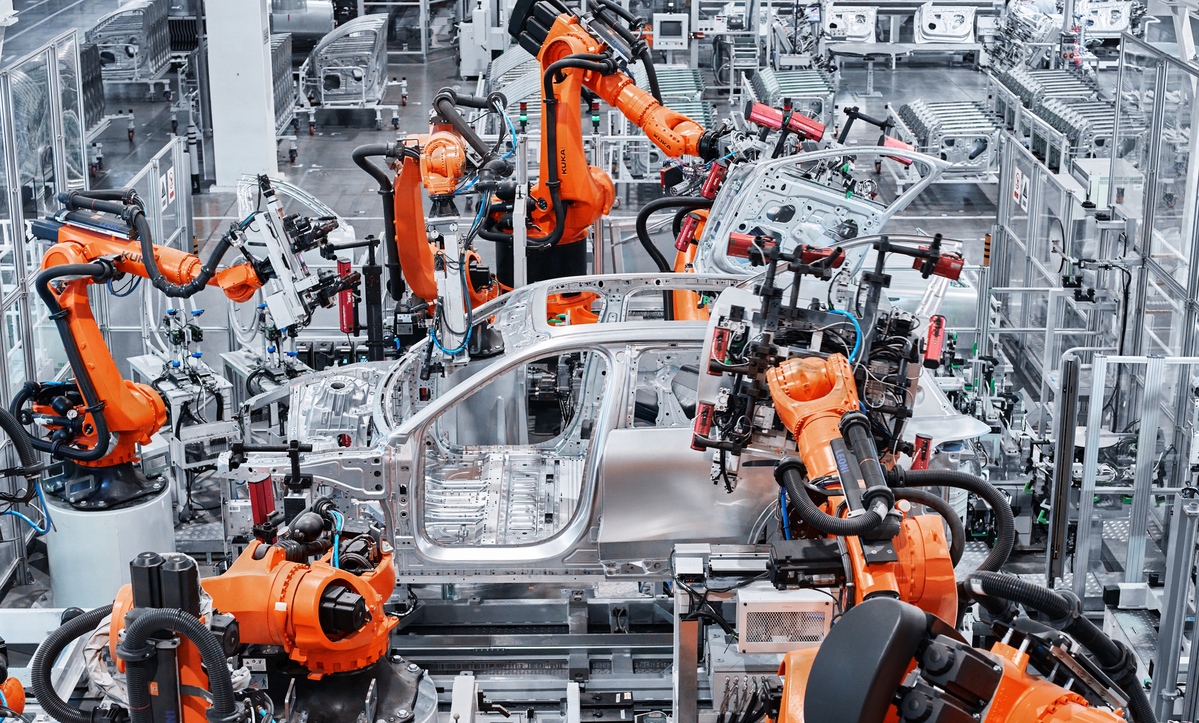

Automated factory

At new energy vehicle maker Nio's state-of-the-art manufacturing hub in the eastern Chinese city of Hefei, Anhui province, an innovative vehicle storage and retrieval platform, aptly named "Rubik's Cube", efficiently manages over 700 vehicle bodies, facilitating a seamless process for personalized production.

Within the bustling workshop, a fleet of over 800 intelligent robots are operating with high precision. These advanced machines are capable of installing four car doors with remarkable accuracy in a mere 98 seconds, achieving a margin of error that does not exceed 0.5 millimeters.

The entire process, from the moment a customer submits an order to the car's completion on the production line, takes just 14 days.

Hefei is rapidly emerging as a hub for NEV manufacturing. The city is fortifying its NEV industry infrastructure by successfully attracting key industry players, including the headquarters of Nio, Volkswagen's modular electric drive platform factory and BYD's Hefei base.

BYD's 2023 annual report revealed that its research and development expenditure for the year soared to about 39.6 billion yuan ($5.47 billion), marking a 112 percent year-on-year growth and surpassing Tesla's R&D spending.

China's NEV sector is at the forefront of technological innovation, with a significant upsurge in R&D activities.

According to a report released in February by Patsnap, a global patent database, the emerging industry saw a 21.9 percent year-on-year growth in the number of invention patent applications filed in 2023, with an impressive 54.9 percent year-on-year increase in overseas patent applications.

"China has been taking a proactive approach in the development of new technologies and materials throughout the NEV industry chain, with a multitude of technological innovations emerging from within the country," said Xia Yingsong, chairman of Zhongding Group.

Zhongding, based in Anhui, specializes in a range of automotive components, including sealing solutions, systems for vibration and noise reduction, fluid management and air suspension systems.

"Capitalizing on the benefits of a vast market scale and a diverse array of product types, Chinese manufacturers are verifying the compatibility and stability of automotive components and forging ahead with innovations amid intense market competition," Xia said.

Smart tech

Tech advancements are also transforming the landscape of solar panel manufacturing in China. At JA Solar's smart photovoltaic module factory in Hefei, an engineer wears 5G-enabled augmented reality glasses and directs his gaze at an assembly machine.

With a simple verbal command to capture an image, the AR system, supported by artificial intelligence algorithms, swiftly presents a detailed equipment inspection report in less than a second, reporting its status: "No vibration, clamping normal, no screw protrusion on the nylon block."

This cutting-edge intelligent system, the brainchild of Hangzhou, Zhejiang province-based startup Rokid, has boosted the production line's efficiency by over 50 percent. This smart assembly line has contributed to half of the factory's overall production output.

Sungrow Power Supply, headquartered in Hefei, is a leading company in China's solar energy sector. It has incorporated large AI language models into its safety warning protocols and launched a prediagnostic system designed to elevate the industry's standards of predictive maintenance.

"With this system, we can continuously monitor vital parameters such as voltage, current and temperature for each battery cell," said Xu Sheng, general manager of Sungrow's smart energy product center.

"For a power station capable of generating electricity of 100 megawatt hours, the system can produce a comprehensive diagnostic report in just a minute," said Xu.

This intelligent solution offers proactive alerts up to seven days before the onset of anomalies and has the potential to enhance operational efficiency by 30 percent.

Growing clusters

As China advances in the realm of new quality productive forces, a substantial surge in total factor productivity is recognized as a core hallmark of this progress.

Within the expansive 6,000-square-meter three-dimensional warehouse at PTL's Liyang facility in Changzhou, Jiangsu province, a fleet of 50 intelligent four-way forklifts and 34 transport robots operate tirelessly.

These machines meticulously orchestrate the logistics of raw materials for lithium battery anodes, all under the direction of an AI-driven robotic system.

The warehouse's operational capabilities have seen a remarkable boost, increasing by 70 percent, while its storage density has been optimized by 30 percent. Moreover, compared with traditional stackers, the system achieves a 30 percent reduction in energy consumption.

The improved logistics efficiency is part of a large picture of the robust supply chain ecosystem that bolsters the NEV industry in China's economically brisk Yangtze River Delta region, where industrial cities such as Hefei and Changzhou are situated.

Particularly, Changzhou has risen to prominence as the nation's hub for the manufacture of power batteries.

Regional specialization, paired with a concentrated pool of industrial expertise, has given rise to a self-reinforcing momentum that spurs innovation and effectively drives down production costs.

In contrast to traditional fuel-powered vehicles, the cycle for updating NEVs has been substantially shortened. Minor updates are usually made on an annual basis, while significant overhauls occur every two years.

Scientists from the Chinese Academy of Sciences have located their research center in Liyang, capitalizing on its proximity to industry chains, which can facilitate the seamless transformation of their research findings into practical applications.

"Over 10 of our suppliers have been relocated here in the wake of our own establishment in the city," said Hua Xia, manager of a power battery plant in Liyang under Contemporary Amperex Technology Co Ltd. CATL has become China's largest automotive lithium-ion battery maker.

A multitude of enterprises within the NEV supply chain, complemented by the region's extensive network of high-speed rail and expressway infrastructure, have created a dynamic industry circle all within a four-hour drive, said Song Tingting, chief analyst in the automotive industry at Huatai Securities Research Institute.

"This approach complies with the principle of local sourcing, which can lead to a significant reduction in transportation costs," Song said.

XINHUA