|

BIZCHINA> Center

|

|

Related

Integration proves profitable for multinationals

By Zhang Qi (China Daily)

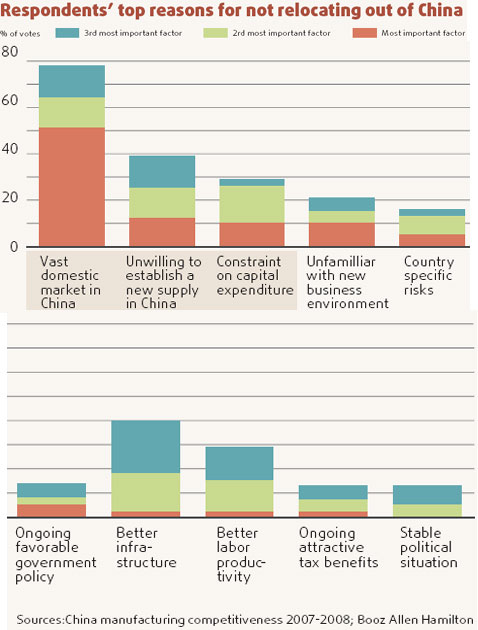

Updated: 2008-10-17 14:05  Costs have climbed so dramatically that about 17 percent of multinational manufacturers in China have decided to shift their operations to other low-cost countries, according to a recent survey conducted by the American Chamber of Commerce (AmCham) in Shanghai and consultanting firm Booz Allen Hamilton. Multinationals will need to bring their best operations to China and fully integrate their export-oriented activities for global markets and domestic sales and distribution networks if they want to retain an advantage as China's operating environment becomes more competitive and costs increase, according to "China Manufacturing Competitiveness 2007-2008". The survey, which questioned 66 manufacturers who are members of AmCham Shanghai's Manufacturing Business Council, showed that three out of four companies lack fundamental best practices in their China operations. Companies integrating their export-oriented activities for global markets with their domestic market operations are achieving higher levels of profitability. The study showed that companies that successfully integrate their China operations enjoy profitability of 29.6 percent, compared with 17.8 percent profitability for those that do not. Half of the multinationals surveyed agreed that India, Thailand and Vietnam are challenging China's position because, among other factors, wages and other costs are rising in China and the increasing value of the renminbi is eroding its cost advantage. Nearly 17 percent of these companies have already decided to move at least some China-based operations to other low-cost countries in Asia and elsewhere. It is clear that China's manufacturing competitiveness is coming under fire: More than half of the surveyed companies - 54 percent - either strongly agree or agree that "China is losing its competitive edge to other low-cost countries in manufacturing". Fortunately, the survey also revealed some good news: Even if China has lost some of its edge, it is still very much in the game. Operating in China still offers huge advantages, which is why 83 percent of respondents said they had no concrete plans to move capacity from China, compared with 17 percent who said they do. Reflecting changing perceptions, manufacturers said the biggest reason to remain in China is access to its vast domestic market. Manufacturers also said they are reluctant to invest in the construction of new supply chains or other infrastructure in other countries. In fact, access to the Chinese market is now a key reason why many companies are coming to the country in the first place: Access to the local market is important to more respondents (70.8 percent) than is the mere use of China as an export platform, whether for the world or Asian markets. This contrasts with 64 percent of respondents citing labor cost savings as their major motive for locating operations in China and 51.7 percent citing access to Asian markets. With regard to executives who believe China is losing some of its competitive edge, the two factors that are most prominent in this shift are the appreciation of the renminbi and the rising prices of components and materials. Other factors they cite are wage increases and poor employee retention.

Companies are feeling much of the cost pressures in terms of white-collar managerial staff. Respondents said they are paying management staff 9.1 percent more every year and paying white-collar support staff 10.3 percent more. In contrast, blue-collar staff costs increased 7.6 percent and raw material costs rose 7.1 percent. On balance, most companies are facing annual cost increases of more than 5 percent in wages and more than 3 percent in materials. At the same time as costs are increasing, China is lagging behind global standards in many operational dimensions. Compared with companies' existing global operations, China scored below standard in terms of important measures such as logistics infrastructure, trade environment, access to technology, management capabilities and the protection of intellectual property. However, there were a number of areas in which China was superior, including the size of the market, availability of a supply base and IT infrastructure. The countries most often cited as possible alternatives to China were India, Vietnam, Thailand, Malaysia and Brazil, in that order. But if companies have failed to thrive in China, the competitive environment is not solely to blame. The survey asked respondents about how they are deploying best practices in their manufacturing, supply chain and logistics operations, and found that none of the best practices are applied by more than 50 percent of the respondents. Their Chinese operations have done their best to integrate their enterprise resource planning or manufacturing resource-planning systems, calculating their inventories, and optimizing product flows. But they are significantly behind in terms of network modeling and optimization, postponement of assembly, segmenting and tailoring supply chains by product characteristics, and statistical forecasting. There does not appear to be a wide variation across industries in this regard: the computer, automotive, electrical equipment, industrial machinery and chemical sectors are roughly equivalent. A large percentage of the companies surveyed - 43 percent - are consciously pursuing the dual objectives of selling products in China and taking advantage of labor cost savings, presumably for goods for export. Indeed, that appears to be the path toward greater profitability in China. Companies that report pursuing dual objectives enjoy profit margins of 29.6 percent while others report only 17.8 percent. The survey paints a complex picture. Manufacturers have a large presence but either have been unable to or have not chosen to implement global best practices across their operations, and they are concerned about the changing cost structure they see unfolding around them. The survey suggested the manufacturing philosophy employed in recent decades by foreign multinationals in China is in need of an overhaul.  (For more biz stories, please visit Industries)

|

久久久无码人妻精品无码_6080YYY午夜理论片中无码_性无码专区_无码人妻品一区二区三区精99