A new era in manufacturing

'Made in China 2025' strategy leads to a spate of transformative technologies

The 19th China International Industry Fair held in Shanghai earlier this month confirmed for lay people what industry insiders knew for a while-that global corporate giants as well as domestic companies operating in China are resolutely digitalizing their factories, systems and processes as if their future depended on new technologies such as intelligent manufacturing powered by industrial cloud platform.

"Industrial cloud platform" refers to an automated manufacturing system that integrates advanced machines, internet-connected sensors and big data analytics. It boosts efficiency, productivity, quality and reliability of output, experts said.

In China, it heralds a new era in manufacturing. It will not only showcase the country's coming of age in technology but set the tone for the rest of the world, they said.

Cloud platforms have become integral to companies' implementation of the "Made in China 2025" strategy, which envisages manufacturing upgrade (or automation wherever possible) so that emphasis is on quality as well, not just quantity.

Eventually, all this tech churn would result in products, services, equipment and systems-all customized for individual consumers and companies, and mass-produced in a jiffy, to highest quality.

Automated cars, superfast PCs, quicker airline and hotel bookings, high-tech online shopping, fool-proof online financial transactions-conceivably, all will be within the realm of possibility.

Earlier this month, Swiss company ABB Group offered a sneak preview of such possibilities. Its new small robot, the IRB 1100, can handle small parts and assembly functions in the manufacture of computers, communications equipment and consumer electronics.

"China's growing demand for high-value products, especially automobiles, and home-related services, offers many growth points," said Peter Tyroller, a board member responsible for the Asia-Pacific at Robert Bosch GmbH, the German mobility, industrial and software conglomerate.

To exploit growth points that Tyroller sees, and for the Made in China 2025 strategy to succeed, intelligent manufacturing and robots are vital, said He Dongdong, senior vice-president of Sany Heavy Industry Co.

No wonder, big companies are investing heavily in those areas, spurring a healthy competition, as smaller firms, their corporate clients across industries, vie to digitalize themselves.

Rather than waiting for government policy to stimulate the market, domestic companies China Aerospace Science and Industry Corp or CASIC, Sany and Haier Group have all pushed their own industrial cloud platforms-Rootcloud, CosmoPlat system and CASICloud respectively-to grab as much market share as possible.

That's because the domestic market is currently dominated by foreign companies (but more about them in a bit).

CASIC, the State-owned defense giant, has been promoting its CASICloud website since June 2015. The website was designed to enable users to benefit from the industrial internet.

"We thought of adopting the industrial internet several years ago as CASIC was seeking to better coordinate its research and production in the manufacture of space products," said Shu Jinlong, chairman of CASICloud Technology Co, a subsidiary of CASIC that is responsible for operating the Chinese platform.

"With the introduction of our internal industrial internet, we have improved the efficiency and productivity of institutes and factories under CASIC. So we hope that the industrial internet could help more businesses."

So far, more than 800,000 businesses, including 3,000 foreign companies, have begun using CASICloud. More than 90 percent of them are small, privately held firms.

Through the website, users can also publish ideas and invite tenders for production, monitoring and control of their factories' machines in real time, collect and analyze data gathered in the manufacturing process as well as optimize their operating systems.

More such wonders were on show at the Shanghai fair. ABB robots showed how they can, through continuous press automation, speed up output rate, churning out up to 14 parts per minute in press lines.

The emerging technologies have already inspired several corporate moves in China.

For instance, in August, Siemens China set up its first research and development center in Chengdu for Mind-Sphere.

In September, it reached an agreement with the Hong Kong Science Park to build the first MindSphere-based digitalization center for a smart city.

Earlier this month, Siemens also signed a strategic partnership with Shanghai Hytera Co, a communication equipment manufacturer, to provide digitalization design consulting, product lifecycle management software, as well as complete automation solutions to the company.

Wang Haibin, vice-president and general manager of the digital factory at Siemens China, said the partnership with Hytera is in line with ongoing efforts to promote digital transformation at local enterprises. "Siemens will continue to leverage advanced technologies in electrification, automation and digitalization to create value for Chinese clients."

Over the past year, Siemens has agreed to provide consultation and solutions for digital upgrading to Chinese companies such as HBIS Group, Baowu Group, Jinyu Biotechnology, Cathay Industrial Biotech, Yunnan Baiyao and Jomoo.

Similarly, in June, Robert Bosch and Baidu, the Chinese online search giant, signed a strategic cooperation agreement on smart mobility in China.

Bosch will be involved in Baidu's Apollo project, which aims to provide open software for the development of automated vehicles.

Under the deal, Bosch will contribute sensors and its Bosch Road Signature map-ping service for vehicle localization. Both companies will provide technical expertise to support the drafting of legislation relating to automated driving in China.

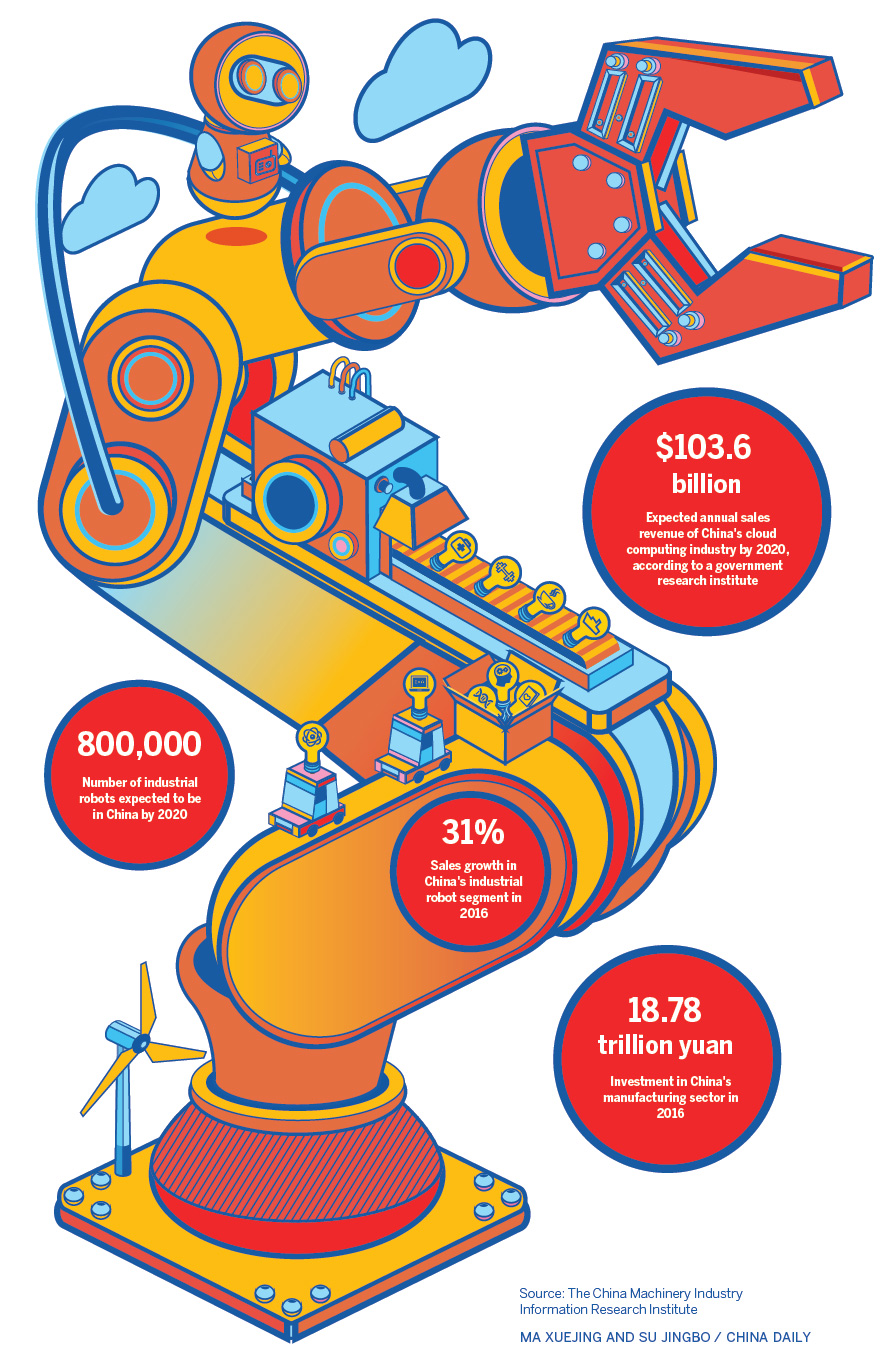

Shi Yong, vice-president of Beijing-based China Machinery Industry Information Research Institute, said cloud platforms will continue to push Chinese companies in many emerging as well as traditional sectors.

They will feel the need to adopt trends in digital, intelligent, service-oriented and platform-based development to enrich their operations, he said.

Globally, the tech wave began to rise in 2014 when the US-based General Electric launched its Predix platform. Germany's Siemens AG followed it up in 2016 by launching MindSphere, a cloud-based open internet of things operating system.

ABB Group and France's Schneider Electric SA, too, announced their own new platforms: ABB Ability and EcoStruxure, respectively, to create a whole new paradigm for the global manufacturing sector.

"Industrial cloud platform is able to enhance cross-industry digital service ability and extend from device to cloud--with devices, systems, solutions, services and a platform that enable customers to improve efficiency, add economic value and ensure precision in their products," said Gu Chunyuan, ABB's president for Asia, Middle East and Africa regions.

Sami Atiya, president of ABB's Robotics and Motion Division, said, "The global manufacturing industry is changing. Rising demand for individualization and customization is increasing the complexity of automation, bringing higher requirements for smart and communicating devices, flexible and efficient automation processes and seamless collaboration across the value chain."

So, China has set a goal for itself to establish up to 300 demonstration projects throughout the country by 2020, including 40 system solution providers with more than 1 billion yuan in annual sales revenue, according to the China Information Technology Industry Federation.

He of Sany said, "Most Chinese manufacturers are still at industry 2.0 phase, in terms of technology. The ones who are working on industry 4.0 need to lead and guide the small ones to upgrade."

A glimpse of China Inc's future

Siemens' cutting-edge digitalized plant in Chengdu, Sichuan province, the first one outside of Germany, epitomizes the industrial cloud that will soon become commonplace in China.

The facility develops and produces industrial automation products like programmable logic controllers and human-machine interfaces for the China and global industrial markets.

Such products are used widely-in automotive, machinery manufacturing, food and beverage, pharmaceutical, glass, cement, metallurgy, power, petrochemical, city subway transportation fields.

At the highly automated unit, raw as well as processed materials are sorted and delivered to the production line concerned at the exact time, without a worker having to lift a finger.

"The key to making this smart manufacturing happen is the collaborative digital platform that is based on PLM software, which is widely used by auto, aerospace and aviation companies," said Chuck Grindstaff, chief executive officer of Siemens PLM Software. "As many as 19 out of the top 20 aviation companies in the world, such as Boeing and Airbus, use our service."