'Urban mining' of waste energizes circular economy

Recyclers turning trash into treasure via new tech, innovative methods

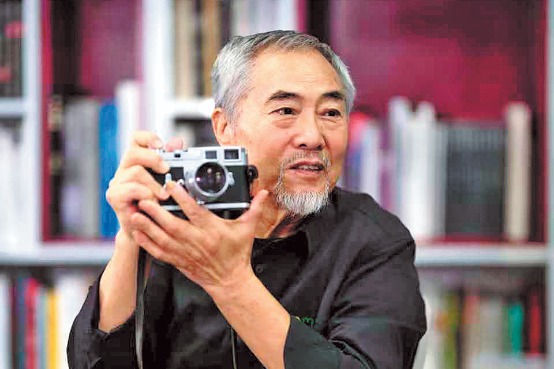

Zhang Wenyong, the founder of Sinone Co, a major green recycling company in Tianjin, recalls vividly the dangers and pollution the waste industry generated 60 years ago.

His father was one of the first waste-recycling station operators in the Ziya area.

"When I was a child, my father rode a 'big iron donkey', an old-fashioned bicycle, through the streets and alleys to collect waste. At night, he would come home covered in dust," Zhang recalled. "Back then, people would find an empty spot, pile up dry wood, throw wires on, burn them and then pick out the copper wires to sell."

In the 1960s, Zhang's family lived in Liuzhuang village, Yanzhuang town, along the Ziya River. "At that time, we didn't dare open the windows at night because of the black smoke," Zhang said with a frown.

Those images and the health and environmental risks are today problems from a bygone era.

A big-data screen in the Tianjin Ziya Circular Economy Industrial Park shows that since 2020, Sinone has recycled over 4.9 million metric tons of renewable waste, transforming it into resources such as copper rods and plastics, which are then transported to production workshops.

Every day, vehicles transport renewable waste collected from more than 10 districts in Tianjin to the national-level economic and technological development zone in Jinghai district.

More than 900 companies involved in the circular economy are located in the zone, a pioneering facility in the country's development of its circular economy.

"Decades ago, there were many small-scale waste recycling workshops in the Ziya area," said Du Yuchun, director of the office at Tianjin Sinone Group.

"However, with technological development and coordinated management, people have developed waste decomposition, purification, and other technologies, leading to a dramatic transformation in this area."

Generational change

Unlike other small-scale waste collectors, Zhang developed his own copper smelting technique, enabling him to conduct preliminary processing and selling of waste.

He quickly made a name for himself in waste recycling in the Beijing-Tianjin-Hebei region.

Zhang and his four siblings grew up following their father through the streets and alleys of Ziya, mastering old techniques and beliefs in "turning waste into treasure". However, the current generation of recyclers thinks about how to "make money without polluting the environment", Zhang said.

In 1996, he registered the Sinone Group and began exploring copper smelting technology.

Today, the company's fire refractory high conductivity method is setting a new industry benchmark. Sinone's self-developed refining process melts waste copper in a furnace at a high temperature, which undergoes physical purification, pressing and drawing, to ultimately produce copper rods with a purity of up to 99.995 percent.

This purity exceeds the standard of ordinary smelted copper, making it widely applicable in high-end manufacturing fields such as aerospace, new energy vehicles, and high-precision copper foils.

Dismantling and recycling scrapped cars is the main work done at Sinone's factory. "The wire and cable recycling and processing equipment can dismantle a vehicle every 60 seconds," Du said.

Pointing at the big data screen, Du said: "Since we began systematic operations, these figures have been constantly updated. Just today, the real-time transaction data has accumulated to more than 5.5 million yuan ($772,280), and the monthly cumulative total has exceeded 3.4 billion yuan."

"Others may see scrapped household appliances as junk, but we see the value of 'urban mining'," Du said.

"From tricycles to sorting machines, what has changed is the equipment, but what remains unchanged is our original intention of treating waste as a resource."

Sinone can recycle and process over 200,000 scrapped vehicles, 1 million tons of steel and aluminum, and 1.5 million household appliances annually, "achieving full-category coverage of renewable resource recycling".

"The tires of a scrapped car can be melted and remade into products; the outer frame can be turned into steel and aluminum and sold to steel and aluminum mills; the plastic can be dismantled and given to plastic granule processing factories to be remade into plastic products," Du said.

"As for nonrecyclable materials like woven fabrics, we collect them separately as solid waste for disposal."

Action plan

In recent years, China has continuously promoted high-level resource regeneration and utilization.

An action plan to promote the large-scale renewal of equipment and the trading-in of consumer goods was issued by the State Council, China's Cabinet, in March last year.

The plan aims to bring more high-quality durable consumer goods into people's lives, smooth the recycling chain of resources, and significantly improve the quality and level of economic circulation, Xinhua News Agency reported.

According to the action plan, the scale of equipment investment in areas including industry, agriculture, construction, transportation, education, culture, tourism and medical care, is planned to increase by more than 25 percent by 2027 compared with 2023.

As of 2027, the recycling volume of scrapped vehicles is planned to roughly double from the 2023 level, while the recycling of used household appliances will increase by 30 percent over the same period, the plan stated.

At the beginning of the 2000s, when the Tianjin Ziya Economic and Technological Development Area was established, Sinone became one of the first enterprises to settle there.

"In 2012, (after being) approved by the General Office of the State Council, the Tianjin Ziya Economic and Technological Development Area became the first national-level economic and technological development zone dominated by the circular economy industry," said Wang Nenglun, a staff member of Tianjin Ziya Economic Development Group Co.

The Ziya area recycles approximately 2 million tons of waste annually and has a production value of nearly 20 billion yuan, with renewable resources making up about 15 to 16 billion yuan of the total.

The area provides approximately 10,000 jobs.

"Ziya park has been developing the circular economy for about 30 years, gradually transforming from the initial primitive dismantling methods to a standardized park model," said Zhang Yanjiang, general manager of Tianjin Ziya Economic Development Group Co.

"This transformation provides a replicable … demonstration path for related industries."

By extending the industrial chain downstream, the park can achieve material recycling, such as modification of old refrigerator shells to produce plastics for the production of new shells, as well as the recovery, purification and reprocessing of wires and cables, Zhang said.

Meanwhile, upstream and downstream enterprises have concentrated and clustered operations in the park, forming a circular interaction among enterprises.

Zhang cited electronics giant TCL and leading green recycler GEM as examples. Moving operations into the park meant they could purchase raw materials there or sell leftover material, giving rise to new business models and enhancing industry synergy, he said.

Meanwhile, China Resources Recycling Group Co will celebrate its first anniversary this month after being established in Tianjin last October. It is the country's first central State-owned enterprise with a primary focus on the circular economy, reflecting the national emphasis on developing the industry.

The group has already established a mobile phone recycling and disposal system across provincial capital cities nationwide.

Assisting SCO members

On Sept 2 — the day after the conclusion of the 2025 Shanghai Cooperation Organization Summit in Tianjin — the China-Shanghai Cooperation Organization Green Industry Cooperation Platform was unveiled in Jinghai district.

"Ziya will deeply focus on the development of urban mining industrial clusters, remanufacturing industry development, and renewable resource cross-border circulation, among other areas," said Zhao Shuang, the deputy secretary of the Party Working Committee and director of the Management Committee of the Tianjin Ziya Economic and Technological Development Area.

"It will deepen cooperation with parks in SCO countries, facilitate international cooperation and exchange channels in the circular economy industry, build an ecosystem for renewable resource industries among SCO countries, and provide a physical model for green and low-carbon development."

The park's renewable resource processing capacity can currently reach nearly 10 million tons annually, he said. It has gone from single renewable resources dismantling to diversified industries such as new energy, new materials, new energy vehicles, and equipment manufacturing. This has gradually realized the "dual-wheel drive" of the circular economy as well as new energy and new materials industries.

"China is not only taking the lead among SCO countries, but also providing a Chinese solution for regional cooperation through its continuously improving circular economy practice system," Zhang said.

"China is assisting SCO countries in building a low-consumption, high-recycling green development model through multilateral experience-sharing mechanisms."

The Ziya Economic and Technological Development Area has established industrial platforms and logistics projects, and cooperation models with SCO countries such as Pakistan, and also shared environmental protection technologies and processing experience, Zhang said.

Against this backdrop, the area is focusing on building a green new industrialization demonstration base, covering approximately 57.5 hectares and with 466,800 square meters of high-quality green-manufacturing factories.

The first phase of the project, covering 30 acres in the northwest of Block B, has met the project conditions.

"In the future, we will conduct investment promotion work targeting SCO countries to assist more multinational enterprises in setting up factories, including those related to the circular economy, new energy, and new materials," said Li Wang, the investment director of the Industrial Demonstration Base Project.

Chen Yijun contributed to this story.

yandongjie@chinadaily.com.cn

Online

Scan the code to watch the video.